A Delaware Basin operator sought a solution for RSS failures resulting from shocks and vibrations in their 8 3/4’’ hole section. The operator’s goal was to protect the MWD/RSS suite via improved drilling efficiency, which would save time by reducing the number of trips due to RSS failure.

The 800 Series HI TOOL® was selected to mitigate the harmful shocks and vibrations, and was positioned below the motor and above the MWD/RSS suite. This would potentially decouple the harmful vibrational shocks generated by the mud motor from the directional tools in the lower BHA. By protecting the lower BHA, the HI TOOL® should reduce wear, increasing the operating life of the MWD/RSS tools. Additionally, the improved dynamics at the RSS should benefit steerability and mechanical energy transfer.

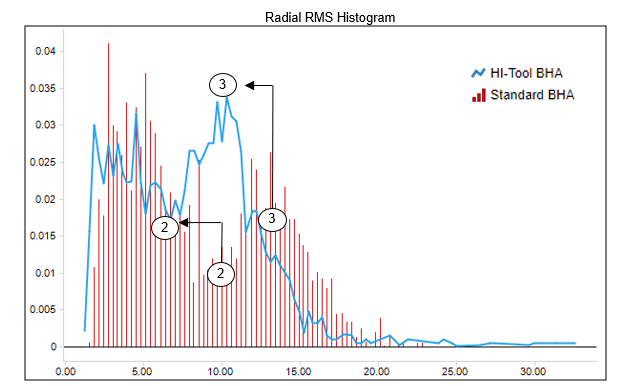

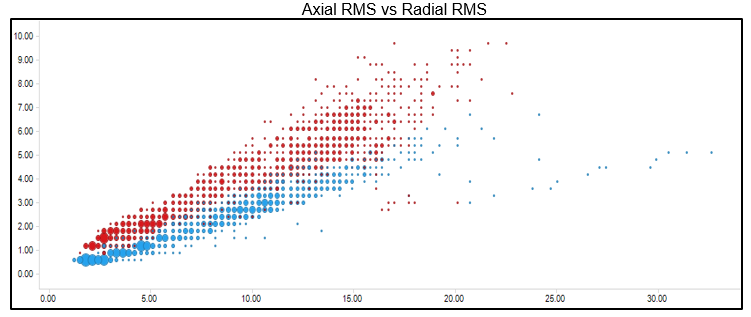

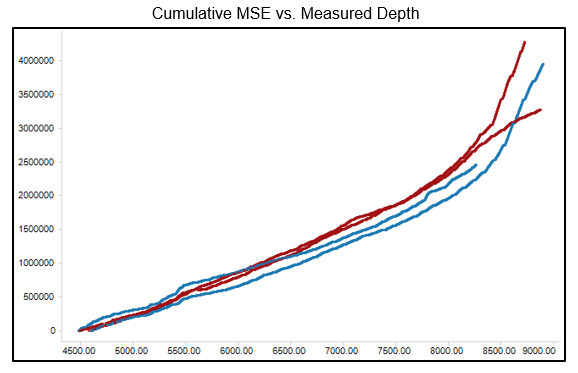

The use of the HI TOOL® in the 8 3/4’’ section successfully protected the MWD/RSS suite from vibrational harmonics. The harmful shocks were reduced and the BHA experienced no excessive wear to the critical components. Use of the HI TOOL® allowed for more efficient drilling with a higher rate of penetration (ROP) and lower mechanical specific energy (MSE). The improved drilling dynamics reduced the number of trips due to MWD/RSS failure.