Customer challenges

- An operator of a Normally Unmanned Installation (NUI) facility in the Southern North Sea, had no individual well monitoring in place

- The customer had invested in a conventional ultrasonic clamp-on meter for export line testing by difference. This conventional ultrasonic clamp-on meter had failed to provide measurement

- The customer was planning well remediation intervention with a perforating programme to increase production

- Existing lower completion limited the thru bore access, the size of perforating guns and potential effectiveness of the remediation

Expro Excellence

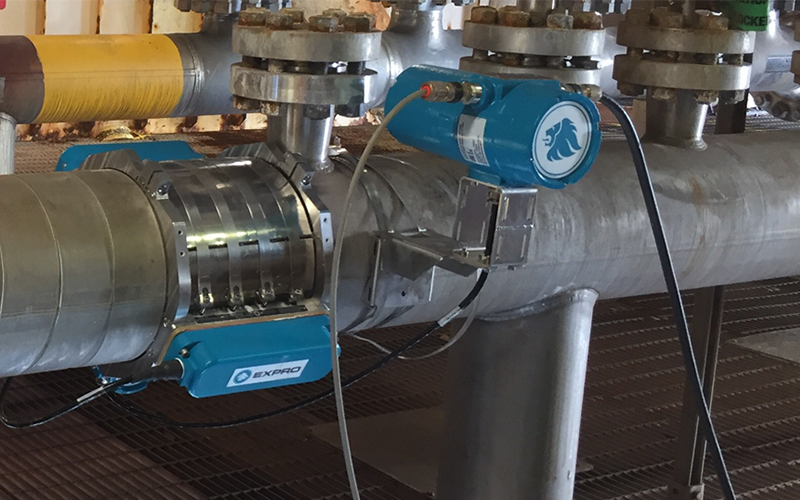

- Expro ActiveSONAR™ flow meter was the proposed solution to perform testing on each individual well and determine the differential pre and post perforation

- The project was performed as a two-stage surveillance operation on the export production header and on each of the four production wells

- The ActiveSONAR flow meter was installed on the production header downstream of the existing ultrasonic clamp-on flow meter. Although this was a less desirable pipe position, Expro successfully collected data

- The ActiveSONAR flow meter unique diagnostics capabilities, identified wetness in the process gas

Value to client

- The customer was able to define and qualify the results of its perforation intervention

- Comparing the flow rate pre and post perforation provided the customer with the confidence of individual well perforation success

- The customer realised an average 40% improvement in peak production on wells that responded to remediation

- This solution eliminated the need and cost of running a production logging tool on each well

- Non-intrusive installation and small footprint, compact design

- The customer received a cost-effective solution previously seen as a cost-prohibitive application