Customer challenges

- A major operator in the Middle East was experiencing high torque issues during an ongoing drilling project. Upon reaching the maximum drill string torque capacity, and still 1,300 feet short of the planned total depth of the 8 1/2" section, the operator was forced to pull out of the hole

- High friction factors were estimated especially in the open hole section after encountering mud losses which affect the hole cleaning process

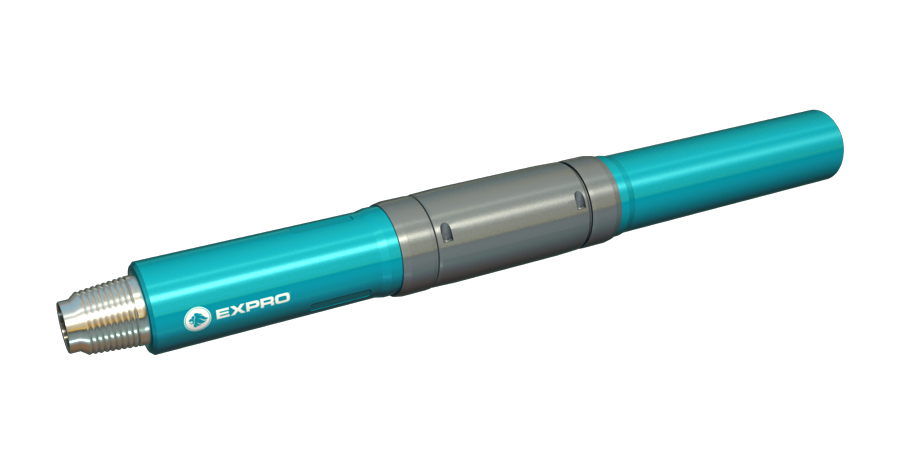

- The customer decided to replace 60 subs of a competitor's torque reduction tools with Expro DSTRs as a solution for their drilling application

Expro Excellence

- DSTRs are the premium torque reduction tool on the market which can handle extremely high side forces while maintaining the lowest friction coefficient due to the robust bearing assembly

- Expro immediately dispatched the 5 1/2"DSTR™ subs to the customer's rig to aid in the reduction of torque. Sixty tools were deployed one tool per stand on the curve section against the high side forces area

Value to client

- The use of the 51/2" DSTRs resulted in the necessary torque reduction and power transmission to the bit, keeping the torque values at surface within the acceptable torque values

- ROP was improved compared to the earlier run without DSTRs as a result of the ability to apply more Weight On the Bit (WOB) and better energy transmissions to the bit

- The customer was able to reach their planned TD successfully with our DSTR's